Germicidal UV-C, 36W Fixture for Effective Room and Surface Sterilization

NLI is proud to offer our very own germicidal fixture for fast, and safe sterilization of medical, dental facilities, laboratories, food processing, retail stores, among many other applications.

The UV disinfection table lamp mainly acts on the DNA of microorganisms, destroys the DNA / RNA structure, and makes it lose the function of reproduction and self-replication to achieve the purpose of sterilization. 36W is suitable for sterilization and air purification in 450 square ft room. When used effectively it can protect from various DNA / RNA-like viruses and bacteria such as Candida albicans, Staphylococcus aureus, E. coli, etc.

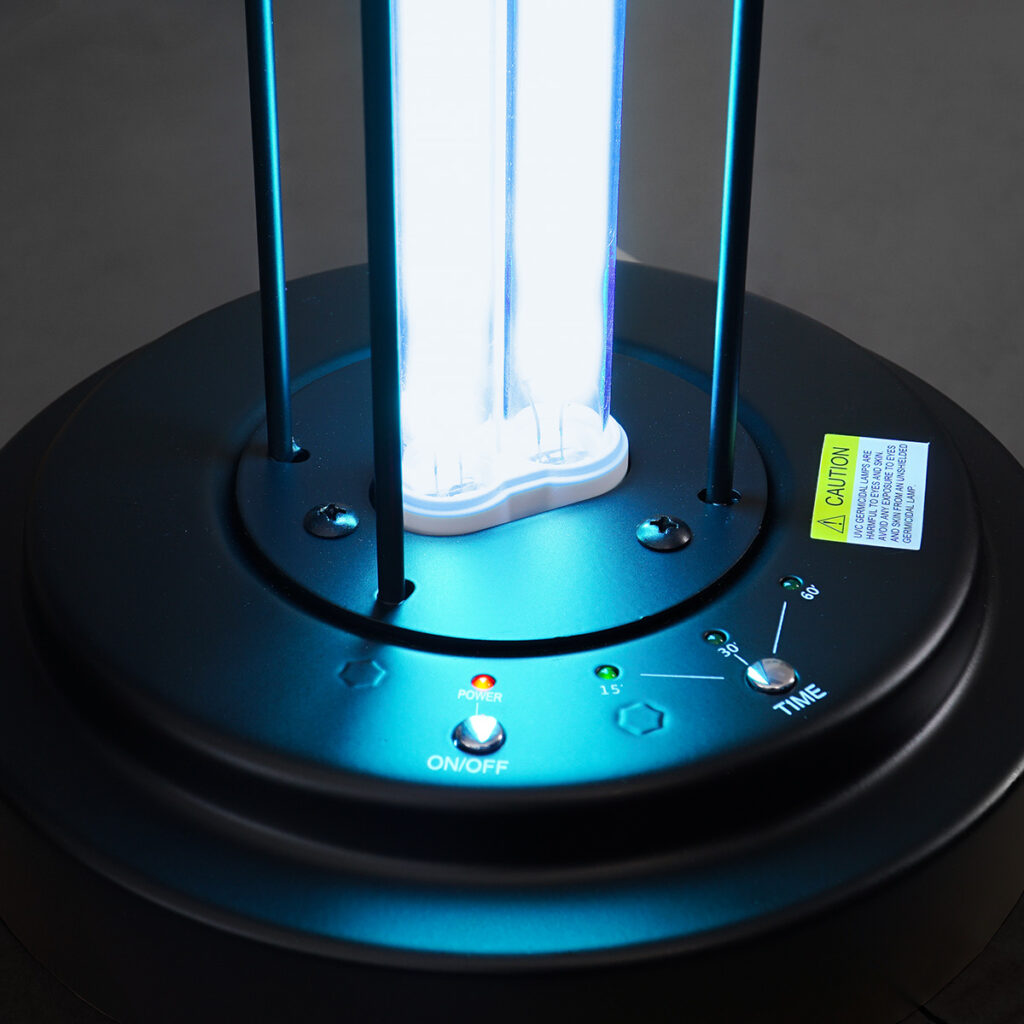

Simple 3-step operation to begin the UVC germicidal sterilization process. Begin by pressing the power button to initialize the fixture, then select the desired power on time of 15, 30, or 60 minutes, finally press the power button once more to start the fixture. There is a 15 second delay to allow any occupants to safely leave the room before the germicidal fixture turns on. For added safety, the above power procedure can also be facilitated using the supplied remote control. The fixture is in stock ready to ship directly from NLI.

Powerful UV-C 254nm wavelength germicidal light. Effectively sterilizes up to 450 sq. ft. area in 30 minutes with 360 degree coverage.

Norman Lamps, Inc. Exclusive, LED High Bay Fixtures DesignLights™ Consortium (DLC) qualified luminaires. Models

Norman Lamps, Inc. Exclusive, LED High Bay Fixtures DesignLights™ Consortium (DLC) qualified luminaires. Models